Upgrading Your Carburetor for Track Conditions

Posted by Steve on 13th Feb 2026

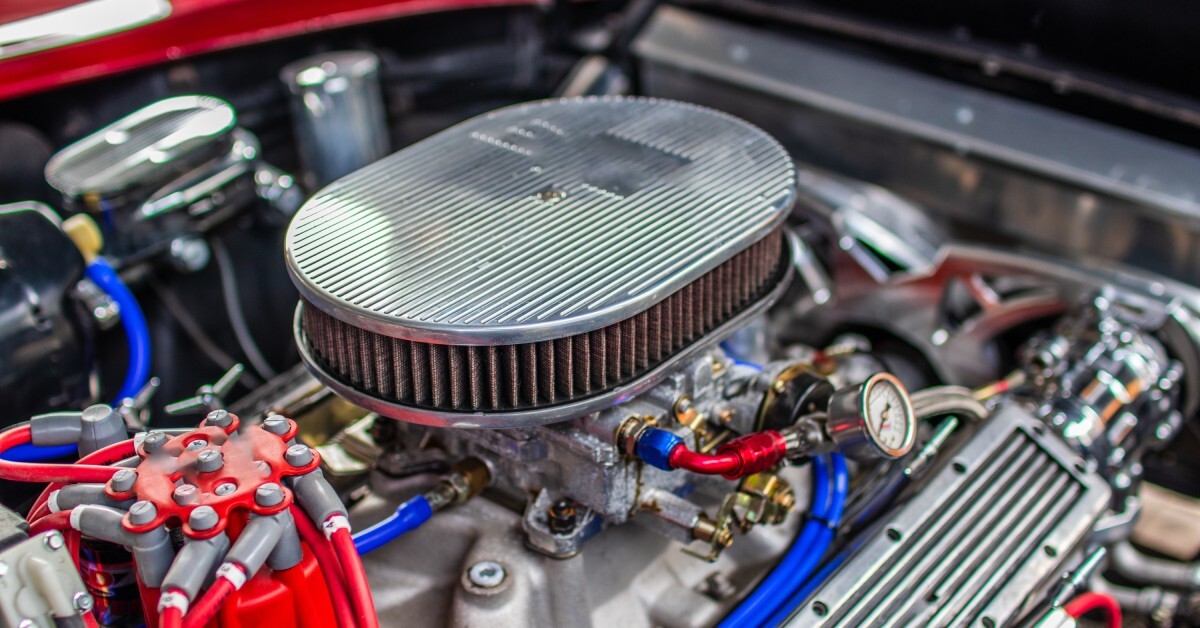

When you take a car to the track, it requires serious preparation. After all, you want to ensure the vehicle survives the abuse of high-RPM racing. Engines demand significantly more fuel and air on a drag strip than when you take them for a cruise down the highway.

Stock components under a vehicle’s hood often lack the capability to keep up with the demands of intense acceleration and high-speed cornering, including carburetors. You need a fuel delivery system capable of handling the pressure. Read on to learn tips for upgrading your carburetor for track conditions.

Calculate Your Real Airflow Needs

You must determine exactly how much air your engine consumes before purchasing a shiny new fuel mixer. Many enthusiasts make the mistake of buying the largest carburetor available, hoping to achieve massive power gains. This approach usually results in a boggy throttle response and poor low-end performance, which kills your 60-foot times.

You need to calculate the cubic feet per minute (CFM) requirement based on your engine's displacement and maximum RPM. A 350 cubic inch small block spinning at 6,000 RPM needs far less air than a 500 cubic inch stroker screaming at 7,500 RPM.

You should be realistic about your redline and volumetric efficiency to avoid over-carbureting the engine. A properly sized carburetor provides crisp throttle response and optimal acceleration throughout the entire powerband.

Consider Mechanical Secondaries for Control

Vacuum secondary carburetors work wonders on street cars where fuel economy and smooth cruising matter most. Track conditions demand an instant response and total control over when the secondary throttle blades open. Mechanical secondaries force the rear barrels open based directly on your foot's position on the loud pedal.

This direct linkage ensures you get full airflow exactly when you need it, without waiting for the engine vacuum to drop. You gain the ability to launch harder and maintain higher RPMs through the shifts with mechanical secondaries.

Match the Carb to the Intake Manifold

Another important tip for upgrading your carburetor for track conditions is to match it up with your intake manifold. The two must work together as a cohesive team to deliver power efficiently. Bolting a massive race carburetor onto a restrictive dual-plane intake manifold creates a bottleneck that strangles horsepower.

Single-plane intake manifolds generally offer better high-RPM performance by providing a direct path for the air-fuel mixture to reach the cylinder heads. You should ensure the flange type matches perfectly to avoid using power-robbing adapters.

The plenum volume of the manifold needs to complement the carburetor size to maintain high intake velocity. A mismatched combination leads to fuel puddling and uneven distribution across the cylinders. You invested heavily in those high-flow cylinder heads, so make sure the induction system supports them.

Account for Camshaft Aggressiveness

Your choice of camshaft dictates the engine's breathing characteristics and directly influences carburetor selection. A radical camshaft with long duration and high lift significantly reduces manifold vacuum at idle. This low vacuum signal wreaks havoc on the metering circuits of a standard street carburetor.

You need a carburetor with adjustable idle air bleeds and replaceable power valve restrictions to tune around a lumpy cam. Racing carburetors often feature modified metering blocks designed specifically for engines with low idle vacuum.

Failing to account for the camshaft profile results in an engine that refuses to idle and stumbles off the line. You want that choppy idle to sound mean, but the car still needs to run cleanly.

Evaluate Booster Designs for Application

Carburetor boosters amplify the vacuum signal to pull fuel from the float bowls into the airstream. Different booster designs offer varying levels of sensitivity and restriction to the incoming air.

For example, down-leg boosters provide excellent high-RPM fuel flow and are common in dedicated drag racing applications. Meanwhile, annular boosters provides better fuel atomization and low-end response, helping heavy cars launch harder.

Choose a booster style that complements your specific racing discipline and vehicle weight. A heavy door-slammer benefits from the increased signal of annular boosters, while a lightweight dragster prefers the unrestricted flow of down-leg styles. Understanding how the booster affects the fuel curve helps you fine-tune the engine for consistent lap times.

Plan for Forced Induction Requirements

Adding a turbocharger or supercharger completely changes the rules for carburetion. Forced induction engines require specialized carburetors sealed against boost pressure to prevent fuel from spraying everywhere.

You must use a carburetor specifically designed for blow-through applications if you plan to mount it before the intake. These units feature solid floats that will not collapse under pressure and special seals on the throttle shafts. The fuel curve needs to be significantly richer under boost to prevent detonation and melted pistons.

Standard naturally aspirated carburetors cannot handle the unique demands of pressurized intake tracts. You risk catastrophic engine failure by trying to adapt a standard carb to a boosted setup.

Choose the Right Float Bowl Design

Fuel slosh becomes a major issue during hard launches and aggressive cornering. Standard float bowls allow fuel to uncover the jets, causing the engine to stumble or stall. Seek out center-hung floats or specialized road racing bowls to keep the jets submerged in fuel at all times.

Drag racers often utilize dual-inlet bowls to ensure the needle and seat assemblies can keep up with fuel demand. Road racers require baffles to prevent fuel starvation during high-G turns. Selecting the correct float bowl configuration ensures the engine never starves for fuel in the heat of battle.

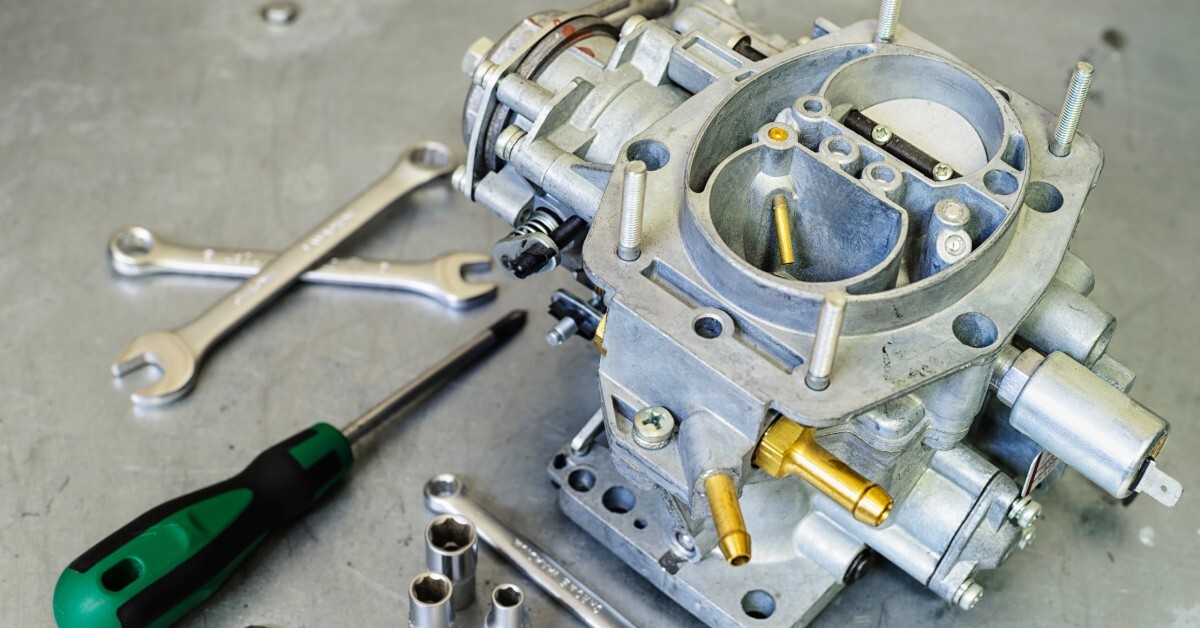

Pick the Correct Jet Sizes

Selecting the right carburetor jets can make or break your car’s performance at the track. Jets control how much fuel flows into the engine. Running ones that are too large can cause the engine to run rich and lose power, while jets that are too small lead to a lean condition and potential engine damage.

Track conditions, elevation, temperature, and even humidity can all shift your optimal jetting, so it pays to experiment and tune on race day. Bring a jet kit, make small adjustments based on how the engine responds, and always keep an eye on performance and spark plug color to dial in the perfect fuel mix.

Building a race car requires careful attention to every component, particularly the carburetor. It acts as the heart of the engine and dictates how well the vehicle responds to driver input. Choosing the correct unit involves analyzing the entire engine combination from the cylinder heads to the forced-induction setup.

You can find the perfect racing carburetors to dominate the competition at Scram Speed today. Contact us today to learn about how our products can help you crush your next run.

US Dollar

US Dollar